overview

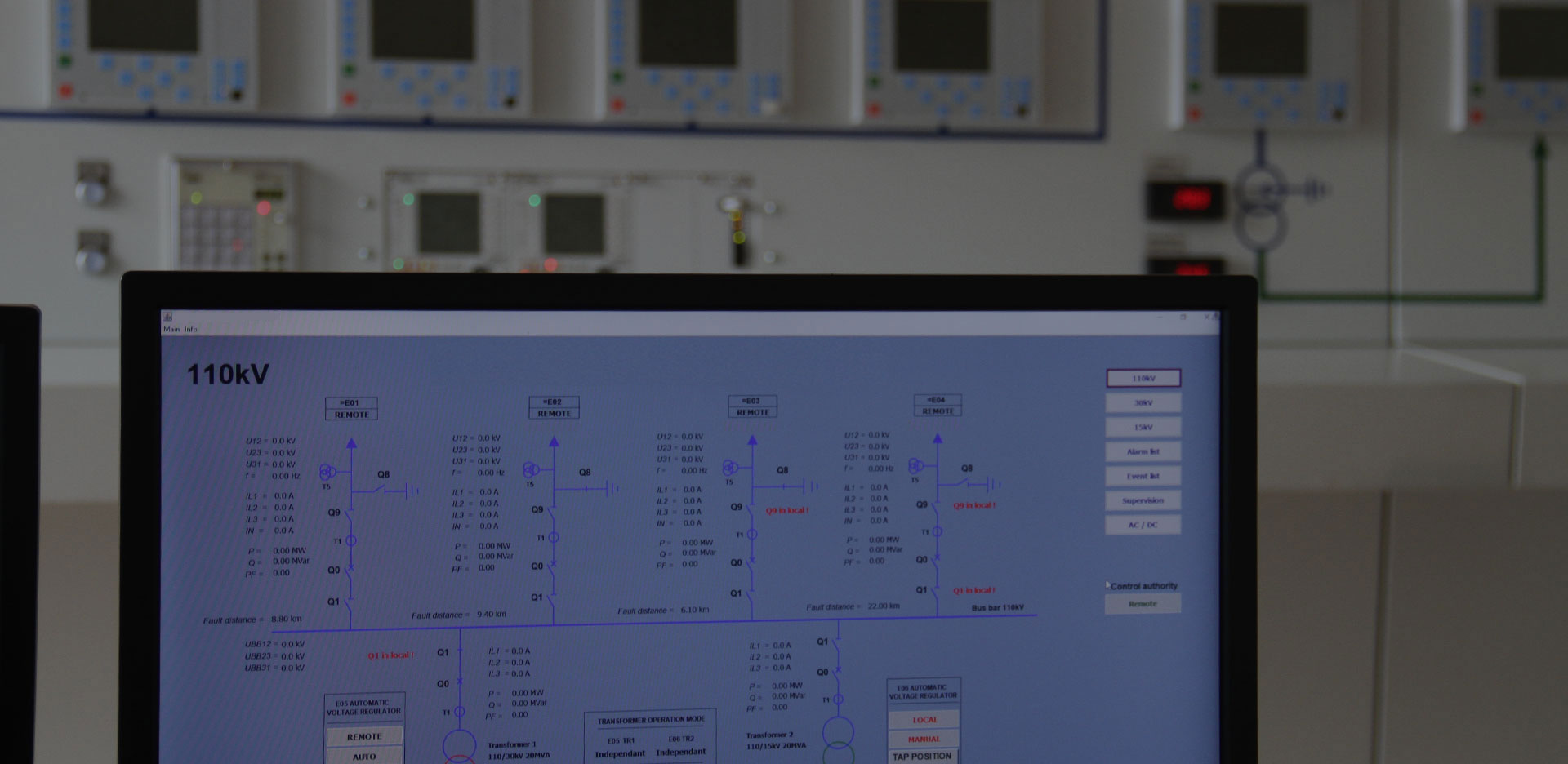

Supervisory control and data acquisition (SCADA) and programmable logic controller (PLC) is the heart of any industrial monitoring and control system. Data from different PLCs are sent to SCADA and Human Machine Interfaces (HMIs) to automate, control and monitor the processes and the subsystems.

We have the required expertise to plan, build, test, installation and commissioning of state of the art PLCs and SCADA/HMIs systems. Our engineers are experts in PLCs from a variety of vendors like Allen Bradley PLC 5, Allen Bradley SLC500, SIMATIC PLC from Siemens, Omron Plc, ABB plc etc. We have the required expertise in SCADA system from ABB, Rockwell Automation, Schneider, Honeywell, Siemens and Emerson Electric.

Our process oriented deployment from our expert engineers will result in significant savings of time and money for our clients, and at the same time improving overall efficiency of the operations.

History of SCADA system

In the early years when electric power systems began developing, electricity generation plants were only associated with their respective local loads. If anything failed in the whole linearly connected system, which could include subsystems like generating plant, power lines, connections, then the lights would be out. Customers had not yet adapted to depend on electricity. Outages, whether routine or emergency, were taken as a matter of course. As reliance on electricity grew, so did the need to find ways to improve reliability.

Generating stations and power lines were interconnected to provide redundancy. As the system expanded and began to scale out in size, it became harder to manage. Solutions were needed to face the challenges of controlling equipment over long distances. To overcome this, operating personnel were often stationed at the important points in this grid system so that they could monitor and quickly respond to any problems that might arise due to any fault or failure. They would communicate with central electricity dispatchers, often employing telephone, to keep them informed about the condition of the system.

Many manufacturing floors, remote sites, and industrial plants relied on personnel to monitor equipment and manually control through mechanical push buttons and analog dials. As the demand for reliable electricity grew even more and as labor became a significant part of the cost of providing electricity, technologies such as SCADA were developed which allow remote monitoring and control of the system's key parameters.